Forged Monoblock Wheel Customization

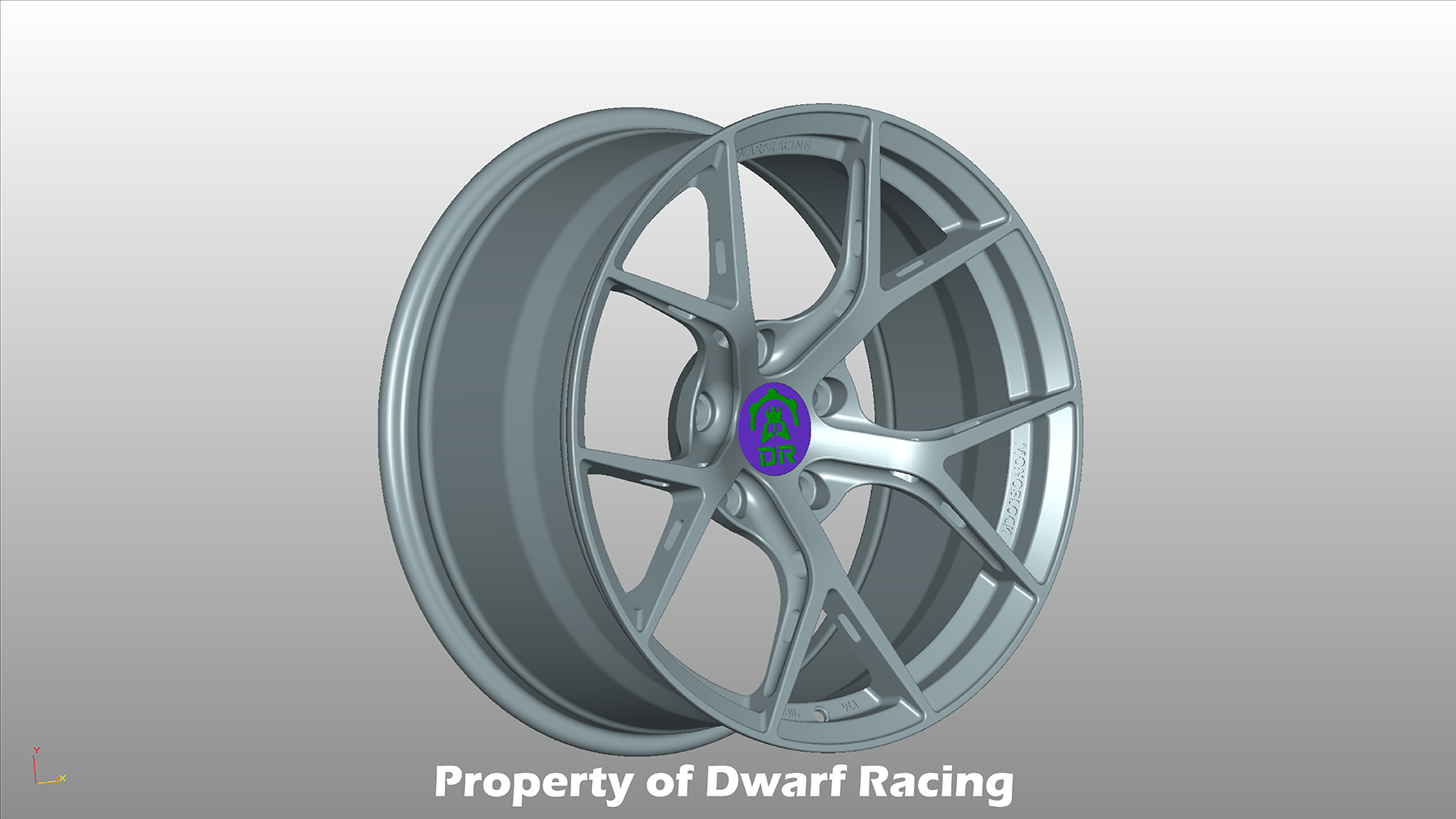

We are proud to say that we are the “WORLD’s FIRST” wheel company to have all our wheel designs hand sketched by our design engineers. We have crafted more than 100 intrigue and exotic wheel designs on our catalogues which are all designed from scratch by our in-house artist. However, if you happen to not like what you see on our catalogues, we welcome challenges.

Please check out our educational video on the “BEWARE” page. At Dwarf Racing®, we want to make sure every of our customer understands and know what they are getting before committing to a purchase. We have generated at least 50 most frequently asked questions to help assist you in your final decision.

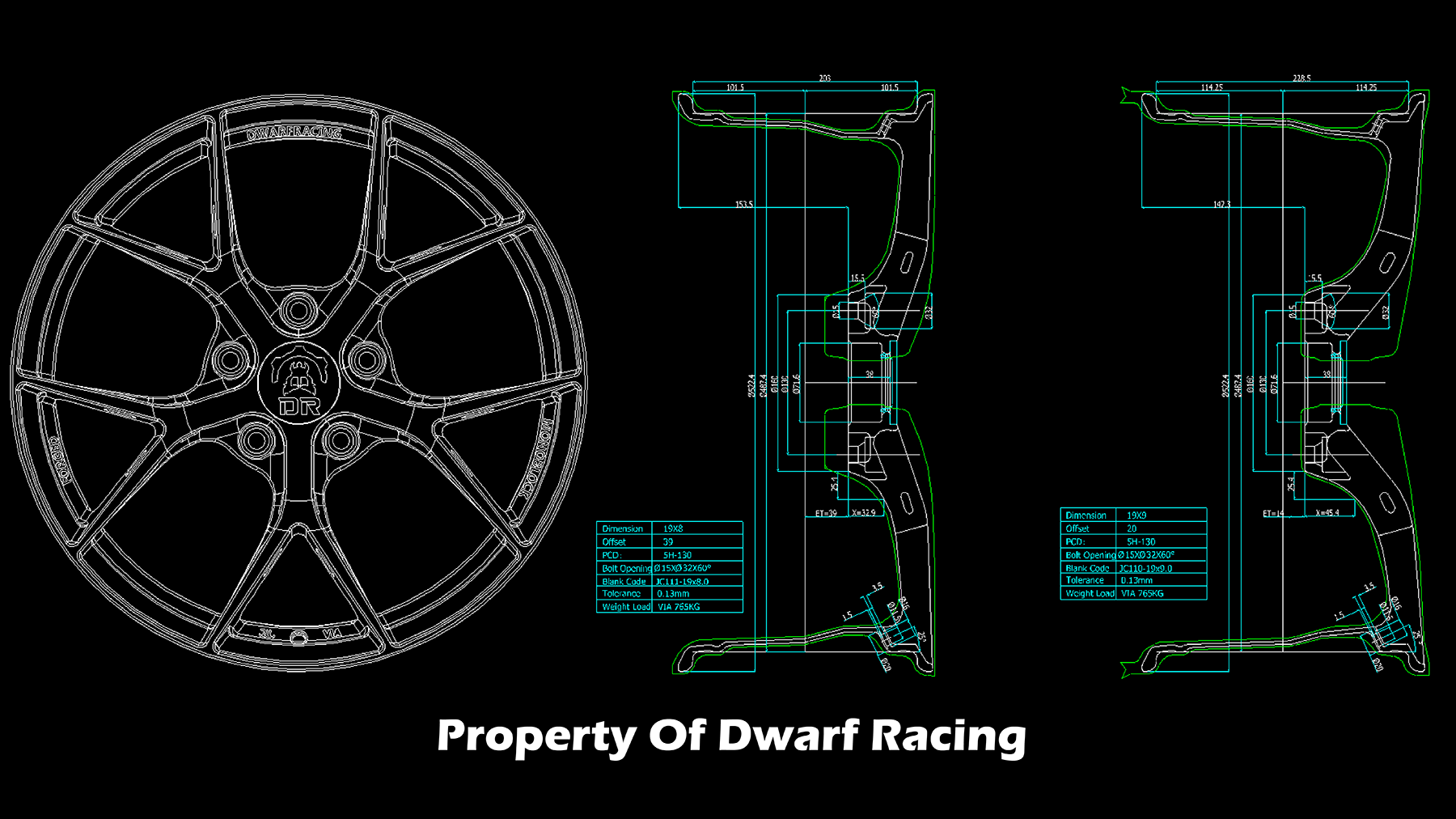

At Dwarf Racing®, we can manufacture a FORGED MONOBLOCK WHEEL (One-Piece) up to a negative offset (extreme) while still maintaining the highest level of SAFETY, PERFORMANCE & STYLE. A simple guideline to offset is when the ET value is HIGHER (+40 +50), the wheels will protrude further in. A LOWER ET value (+20 +10 -10), results in moving the wheel protruding further out of the wheel arch.

Our production can support the crafting of FORGED MONOBLOCK WHEELS from 16 inches to 24 inches in diameter.

Cast Wheels & Flow Foam Wheels will not be able to achieve such a low aggressive offset (One-Piece) while still maintaining SAFETY factor intact. They are often compensated by making the wheel into a (Two-Piece) wheel to achieve the required offset for the specific vehicle.

Most OEM/Original Cast wheels exit from the factories with (+40 +60) offsets, performance vehicles will come lower.

A well-crafted FORGED MONOBLOCK WHEEL is a God-given piece of engineering product that is worth an eternal admiration. We know of an acquaintance who has been using a custom Monoblock RUF Wheel on his Porsche 930 (911 Turbo) for the past 20 years with no wheel warp issues.

If you wish to further personalize a wheel design, you can take an example from our current catalogue or even your own design or photo, send it to us, state your specifications, we will assist in conceptualizing and complete the final execution.

If you do see a DESIGN you like on our CLASSIC or EXOTIC Catalogue and wish to have it crafted using our AERODYNAMICS TECHNOLOGY, do let us know, we will gladly assist.

Do note that our engineers will access the possibilities of the design and recommend the best structural design for the recommended application. For example, off-road rally cars focus on strength and durability rather than visual appearances. Our metals are periodically being tested to ensure the strictest quality control & assurance. (Metal Test Certifications)

Do note that all our “FORGED” wheels come default with a “MARK OF AUTHENTICITY” certification which is linked to our dedicated cloud-based servers.

On-site inspection and measurement are also available upon request (ONLY SINGAPORE), however this is chargeable for a fee but will be reimbursed once an order is confirmed. We have a physical catalogue of MORE THAN 60 COLORS for you to choose. Due to the COVID-19 situation, we have also included a “Door-step Installation” option for our clients. (ONLY SINGAPORE). Otherwise, by default, every set of wheels will be installed at our facilities.

Our current production lead time will be around 6-12 weeks; however, this time is based on multiple factors. In some cases, they may take longer if an unforeseen occurrence happens such as a faulty machine, logistics issues or a sudden increase in orders. Dwarf Racing® will be fully committed to all our clients around the world and take full responsibility to notify you if such an occurrence arises.

You are most welcome to visit our showroom (Only by Appointment) currently located in SINGAPORE. We have our full range of colors and exotic design displayed. You can for ONCE IN YOUR LIFE feel and touch, the exact forged aluminum 6061-T6 mono-block that goes into production. However, due to COVID-19 situation at this point of time we are unable to disclose our production facility information and no visitors are allowed. We have signed certain non-disclosure agreements (NDAs) and consortium agreements that do not allow us to expose our facilities as well.

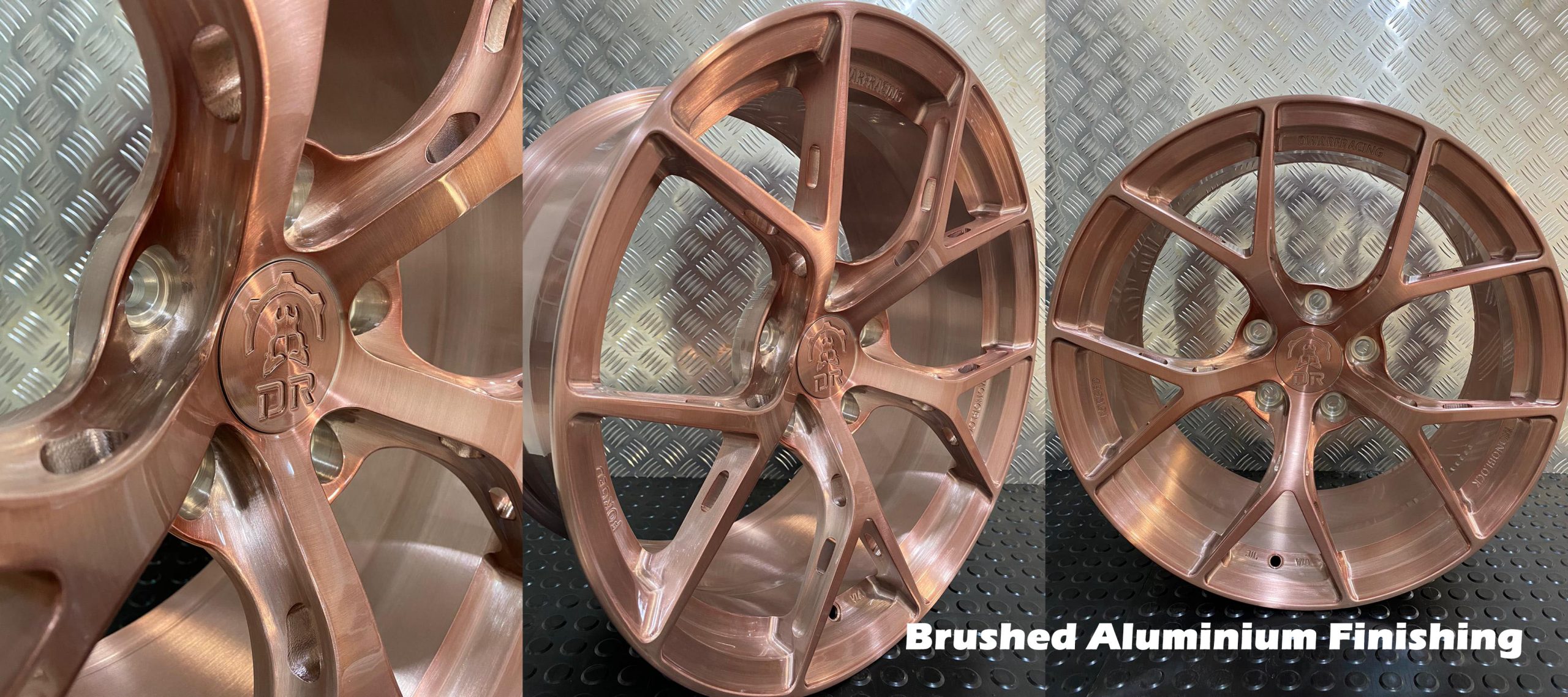

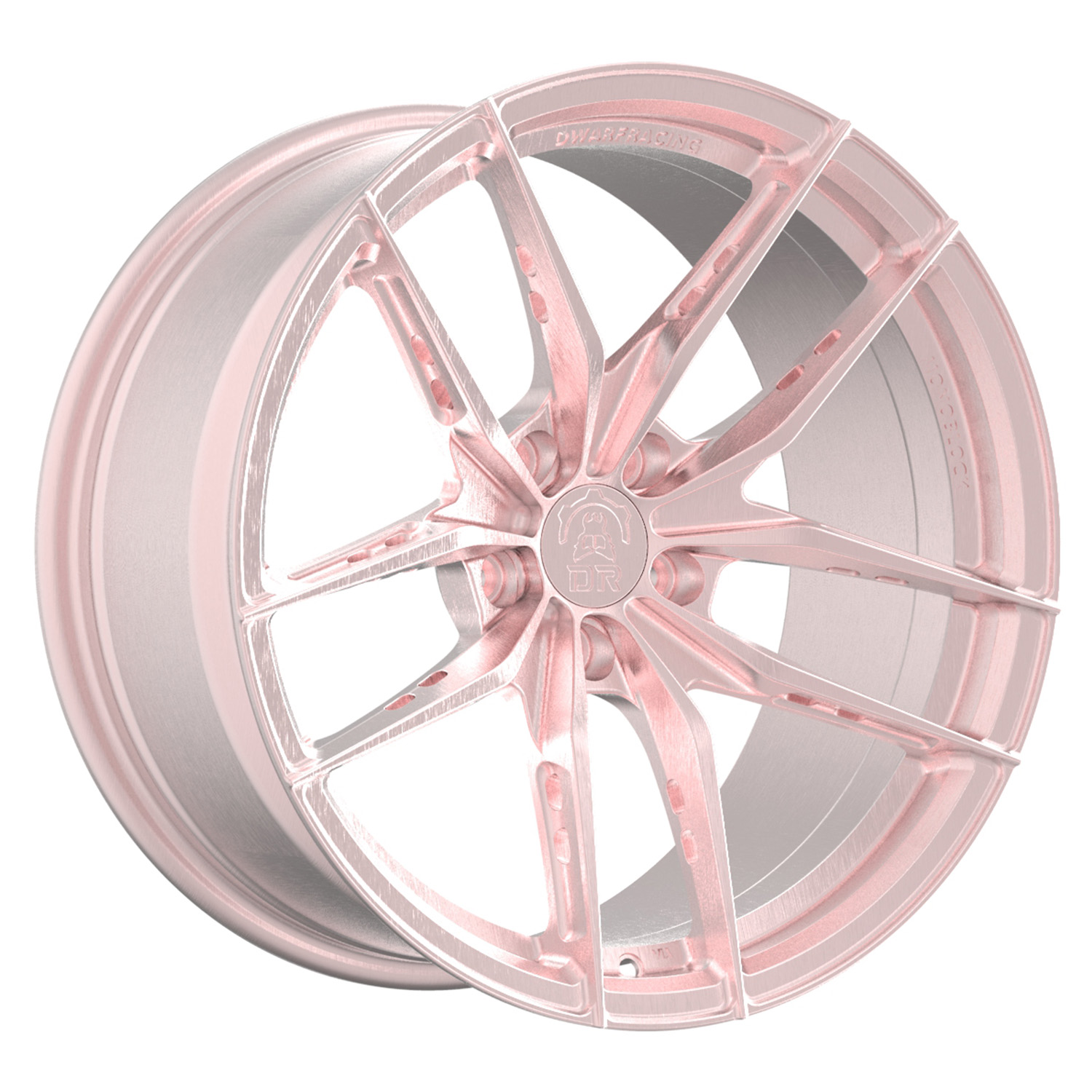

We HIGHLY RECOMMEND our raw “BRUSHED ALUMINIUM FINISHING” to showcase the craftsmanship of the finest CNC ENGINEERING at works with over 60 COLORS to choose from. Believe us, when you see them in real, you will truly understand what a “FORGED” wheel is.

Yes, we are able finish the wheel in “POWDER COATING” wheel paint option with over 30 COLORS to choose from on our catalogue. HOWEVER, we do not encourage this type of finishing. As this is often used by many other manufacturers to COVER the flaws of a wheel, be it ADVERTISED AS FLOW FORGED, FLOW FOAM FORGED, FORGED HYBRID, a “POWDER COATING” finishing term is often used to upsell the product.

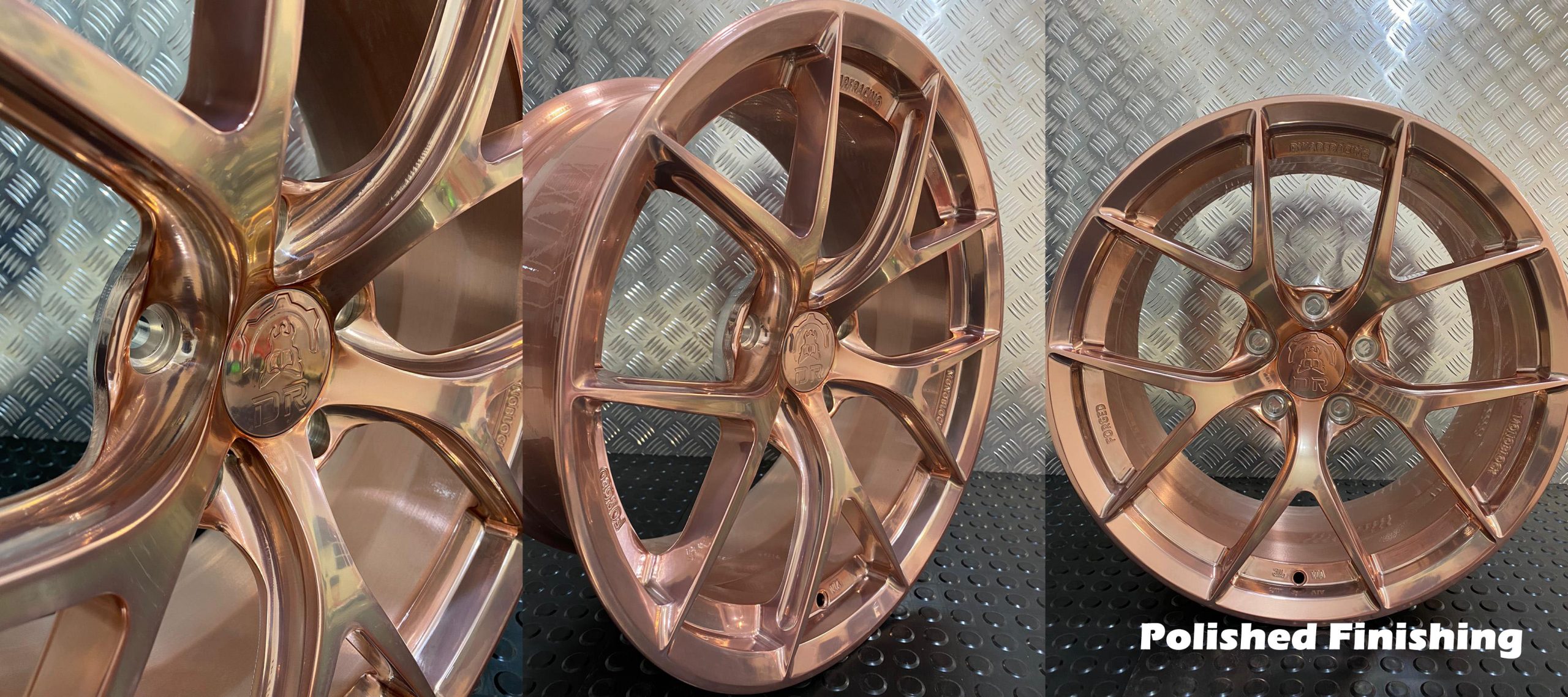

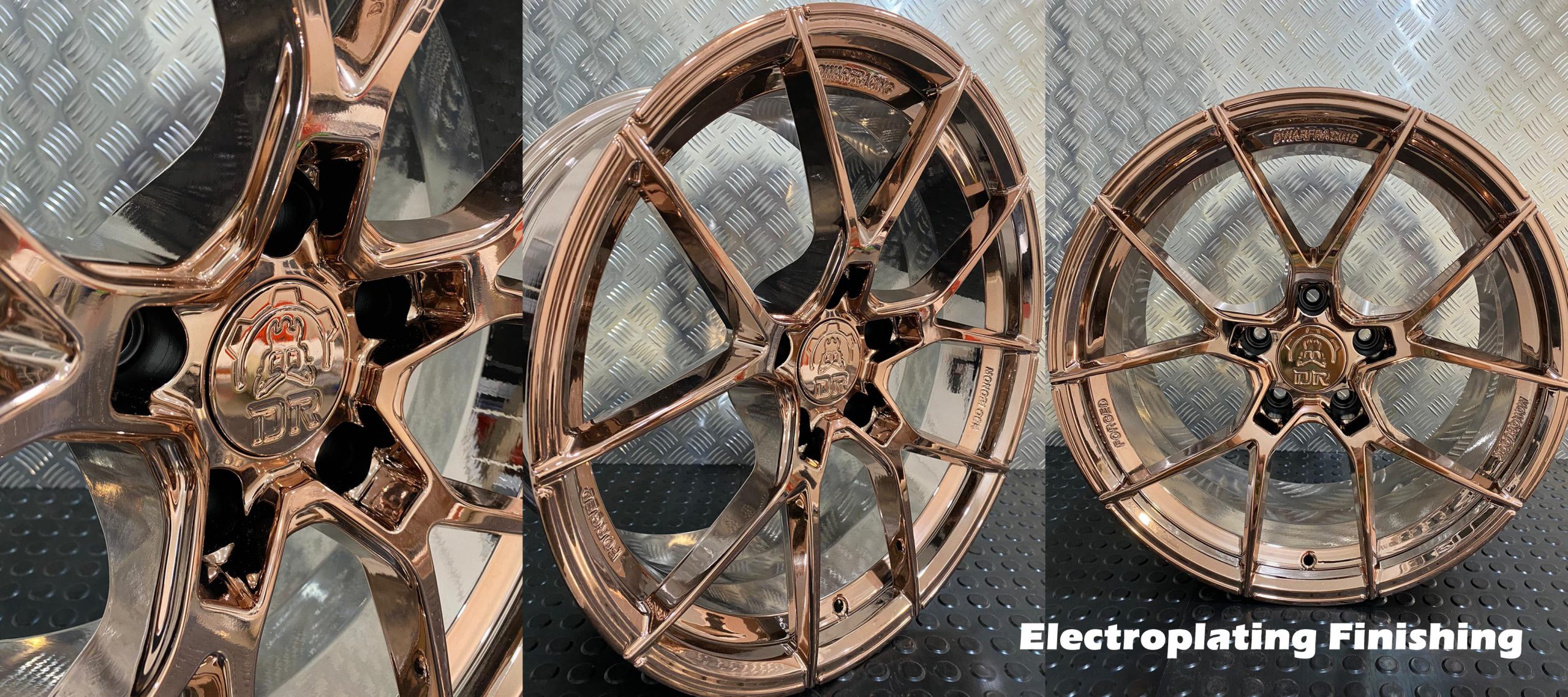

We are also able to finish the wheel in “POLISHED” surface finishing, which will have a chrome-like effect, HOWEVER, not as reflective as “ELECTROPLATING” finishing. A “POLISHED” finishing is more durable & has lesser maintenance as compared to a “ELECTROPLATING” finishing.

INSANE EXOTIC finishing “ELECTROPLATING” is also available to those who want to be out of the world. 10 COLORS are currently available.

For those who are ordering from out of SINGAPORE. We do support LIVE CHAT or LIVE VIDEO to help assist you in the final color and/or surface finishing LIVE from our physical catalogues and showroom.

Check Out Our Product Videos on Youtube